- Home »

- Harrison Machine Co. Products »

- Harrison Core Machines »

- Harrison Core Machines - Dual Station »

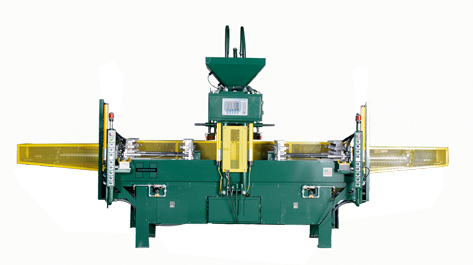

- Hot Box & Warm Box Core Machines- Dual Station

Hot Box & Warm Box Core Machines- Dual Station

Hot Box & Warm Box Core Machines

Hot Box & Warm Box Core Machines - Dual Station Productivity & Utilization

- Increases Operator Output: One Operator runs 2 jobs at the same time.

- Semi-Automatic Operation: the machine drives the core making process for predictable results.

- Quick Change Core Box Mounting System: available, change boxes in just a few minutes instead of the better part of an hour.

- Production During Heat-Up: run full production on one station while the other station’s box is heating up.

- Advanced Temperature Control & Heat Transfer: helps to make the cure cycle more efficient and heats boxes up much faster.

- High Speed Operation: high efficiency pneumatics enable faster Dual Station machine times than most other single station machines.

- Only Shell Machines Capable of Higher Productivity than Cold Box Machines: because of the nature of our Dual Station System and the Hot Process our machines have a much shorter machine time part of the cycle.

Hot Box & Warm Box Core Machines - Dual Station Unparalleled Flexibility

Dual Station Multiple Operational Modes to suit the constantly changing demands of most Foundries by running at the same time:

- Automated Unloading available

- (2) Short Jobs

- (2) High Volume Jobs

- (2) Customers at Same Time.

- Both Parts of a (2) pc. Core

- Three Piece Boxes capability

- Large Core on (1) Station, Small Core(s) on Other Station

- Automatically Runs Multiple Short Cycles on (1) Station to (1) Long Cycle on Other Station

- Long Run on (1) Station & Jobbing Work on Other Station

- Hollow Core(s) on (1) Station & Solid on the Other Station, or Same on Both Stations

- Small Box on (1) Station & Large on the Other Station, or Same on Both Stations

Hot Box & Warm Box Core Machines- Dual Station Reduced Energy & Emissions

- Superior Productivity, Utilization, and Flexibility: equals fewer Harrison machines are required to meet capacity demand.

- Fewer Machines equal less core making energy used.

- Lower Energy Usage equals less related energy consumption emissions.

- Lower Emissions equals less cost for regulations compliance and lower remediation expenses.

- Higher Productivity & Fewer Machines means more cores per energy & labor unit equals lower operating cost.

- Lower COST-per-CORE equals a quick payback & higher margins equal an increased Competitive Advantage.

Hot Box & Warm Box Core Machines - Dual Station Specs

| Model | Max Box Capacity | Blow Cap. |

|---|---|---|

| 1016-DW | 10”H x 16”W x 6”D | 20lbs / 5L |

| 1616-DW | 16”H x 16”W x 10”D | 35lbs / 9L |

| 1818-DW | 18”H x 18”W x 10”D | 40lbs / 10L |

| 1824-DW | 18”H x 24”W x 10”D | 57lbs / 15L |